Vertical Packaging Machine: High-Efficiency Packing Solutions for All Industries

Industry news

Vertical packaging machines, also known as vertical form fill seal machines (VFFS machines), have become essential equipment in modern industrial production. From food and beverage to chemicals and daily consumer goods, these machines enable efficient, reliable, and versatile packaging solutions. Choosing the right vertical packaging machine is critical to ensuring product quality, production speed, and operational stability.

How Does a Vertical Packaging Machine Work?

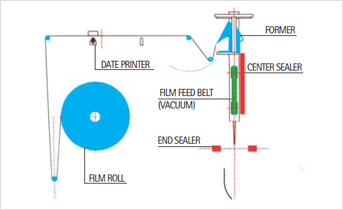

Vertical packaging machines operate through a coordinated sequence of automated actions:

1. Film Unwinding and Transport

2. Bag Forming via a forming collar and tube

3. Product Weighing and Filling

4. Sealing and Cutting (back seal, three-side, four-side as needed)

5. Discharge of Finished Package

These machines integrate multiple subsystems including:

- Film transport system

- Weighing and dosing system (multi-head weigher, auger filler, cup filler, liquid pump)

- Sealing unit (heat seal or cold seal)

- PLC-based control and HMI touchscreen

Core Components & Weighing Tool Options

| Weighing Tool | Ideal For | Key Advantages | Selection Notes |

|---|---|---|---|

| Multi-head Weigher | Snacks, candy, dried fruits | High speed, high precision, combinatorial weighing | Hopper quantity, precision level |

| Auger Filler | Powdered products (coffee, milk) | Dust-free, precise dosing, screw-based filling | Screw pitch, anti-dust design |

| Volumetric Cup Filler | Grains, beans, seeds | Low-cost, mechanical simplicity | Cup size, material, adjustability |

| Liquid Pump | Liquids (water, sauce, detergent) | Accurate volume, hygienic design, versatile flow rate | Pump type (peristaltic, piston), corrosion resistance |

Application Scenarios

Vertical packaging machines are widely used across:

- Food Industry: Snacks, biscuits, frozen foods, condiments

- Grain Industry: Rice, beans, seeds, granular cereals

- Chemical Industry: Fertilizers, detergents, agrochemicals

- Daily Necessities: Shampoo, lotions, dishwashing liquid

- Beverage Industry: Bagged water, juices, tea beverages

- Pharmaceuticals: Powdered and granulated medicines

Case Example: A dried fruit packaging company used a multi-head weigher vertical packaging system to increase packaging speed by 40% while maintaining consistent weight accuracy within ±0.5g.

Key Considerations When Choosing a Vertical Packaging Machine

- Product Characteristics: Powder, granule, liquid, flowability, corrosiveness

- Packaging Specs: Bag size, material type, sealing method, required speed

- Integration Requirements: Compatibility with upstream/downstream equipment (conveyors, cartoners)

- Automation Level: Need for auto-detection, recipe memory, remote control

- Budget and Support: Price-performance ratio, supplier reliability, after-sales service

Future Trends

- Increased Intelligence: AI-driven predictive maintenance, real-time analytics

- Greater Sustainability: Eco-friendly film compatibility, lower energy consumption

- Flexible Formats: Custom-shaped bags, resealable pouches

- System Integration: Seamless connection to WMS, ERP, and MES systems

Frequently Asked Questions

Q1: What types of products can this machine package?

A: Everything from powders, grains, snacks, liquids, to pharmaceuticals—using the appropriate filler tool.

Q2: What’s the difference between vertical and horizontal packaging machines?

A: Vertical machines are ideal for free-flowing products and space-saving setups, while horizontal machines better suit solid items like cookies or hardware.

Q3: How do I know which filler system to choose?

A: It depends on your product type. Powder → auger; liquid → pump; granular → cup or multi-head weigher.

Q4: Can the machine integrate with other systems?

A: Yes, our vertical packaging machines support modular integration with conveyors, labeling units, and robotic palletizers.